问题描述

想让你的K230开发板拥有"紧盯"手部的超能力吗?今天就带你解锁基于PID算法的手部追踪技能,只需简单代码,让二维舵机云台跟随手部移动,科技感拉满!

一、核心原理:PID 算法+视觉识别

手部追踪的核心是让舵机云台根据摄像头捕捉的手部位置,实时调整角度,始终将手部锁定在画面中央。这背后的"智慧大脑"就是PID控制算法:

- P(比例):根据手部与画面中心的偏差,直接调整舵机角度,偏差越大,调整幅度越大

- I(积分):消除长期存在的微小偏差,让追踪更精准

- D(微分):根据偏差变化速度,抑制过冲和震荡,让追踪更平稳

配合K230强大的视觉识别能力,就能实现流畅的实时追踪啦~

二、 准备工作:硬件与环境

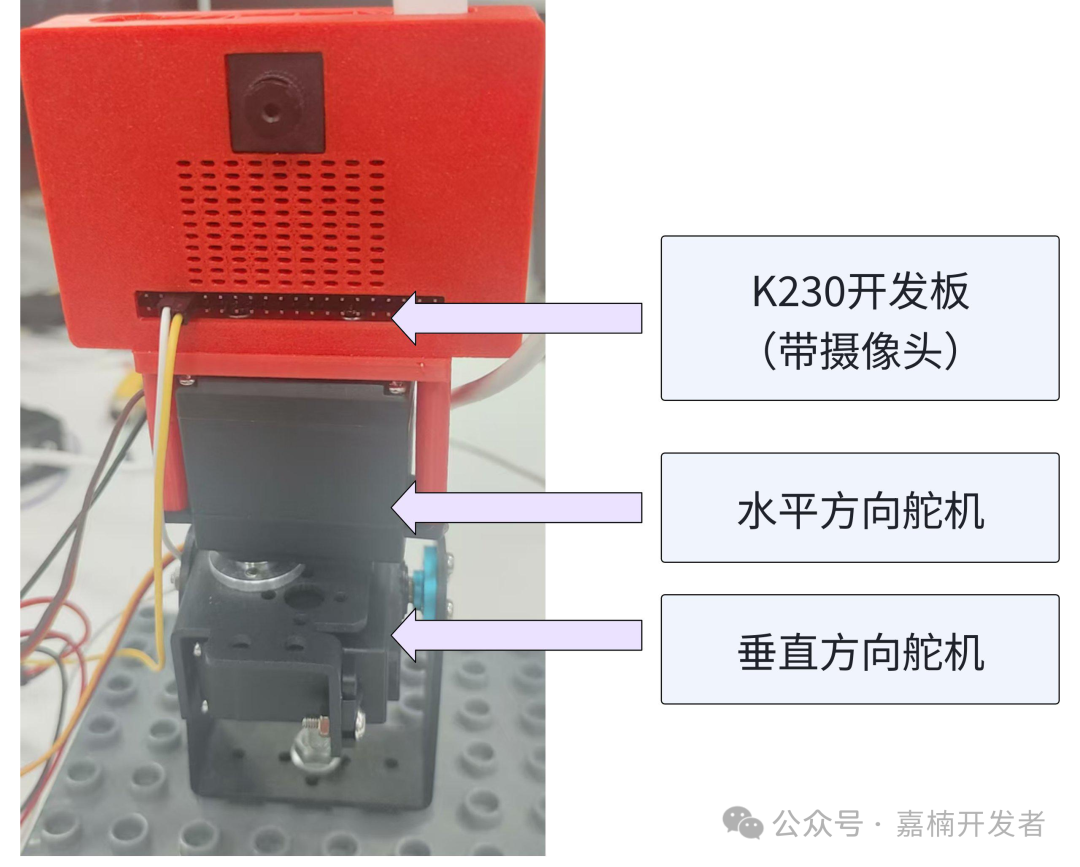

1. 所需硬件

- K230开发板(这里我们使用的是庐山派,需要接上摄像头)

- 舵机云台2个(淘宝购买,本次demo舵机链接:https://item.taobao.com/item.htm?id=17392171945)

- 外部电源,需要5V,1.5A以上供电能力

- 电脑

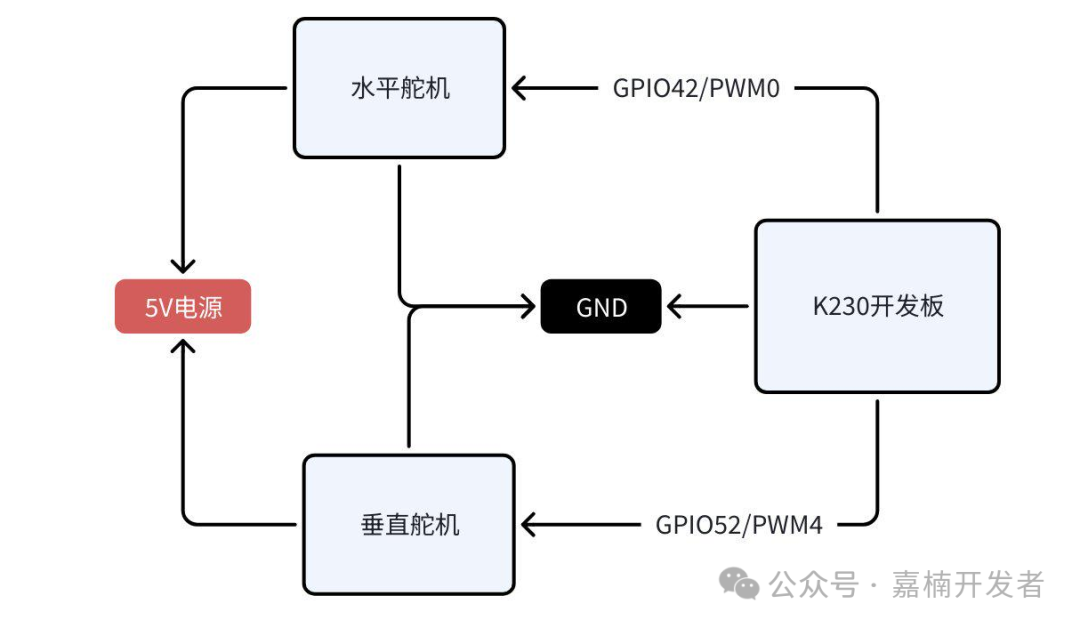

硬件连接:

连线方式

⚠️ 重要提示:舵机需单独外接 5V 电源供电,请勿直接使用开发板的 5V 输出。若供电不足,可能导致舵机运行卡顿、扭矩不足甚至损坏设备,影响追踪效果哦~

2.软件环境

CanMV K230官方固件

- 下载链接:

https://kendryte-download.canaan-creative.com/developer/releases/canmv_k230_micropython/daily_build/ - CanMV IDE

下载链接:

https://www.kendryte.com/zh/resource?selected=0-2-1 - 参考代码

/canmv/sdcard/examples/03-Machine/handle_detect_servo.py

三、实战步骤: 从0到1实现追踪

1.步骤1:搭建基础框架

首先导入必要的库,包括视觉处理、舵机控制和PID算法相关模块:

from libs.PipeLine import PipeLine

from libs.AIBase import AIBase

from libs.AI2D import Ai2d

from libs.Utils import *

import os, sys, ujson, gc, math

from media.media import *

import nncase_runtime as nn

import ulab.numpy as np

import image

import aicube

from machine import PWM, FPIOA

import time

步骤2:配置硬件接口

将GPIO引脚配置为I2C功能,连接舵机驱动板

def servo_init():

# 初始化水平方向控制PWM

fpioa = FPIOA()

fpioa.set_function(PWM_PIN, fpioa.PWM0)

g_pwm = PWM(0)

g_pwm.freq(PWM_FREQ)

move_servo_x(60) # 初始到中间位置

fpioa.set_function(PWM_PIN_H, fpioa.PWM4)

h_pwm = PWM(4)

h_pwm.freq(PWM_FREQ)

move_servo_y(60)

步骤3:编写PID控制器

创建PID类,实现核心控制逻辑:

class PID(object):

"""PID控制器类(保持原逻辑,确保稳定性)"""

def __init__(

self,

Kp=1.0,

Ki=0.0,

Kd=0.0,

setpoint=0,

sample_time=0.01,

output_limits=(None, None),

auto_mode=True,

proportional_on_measurement=False,

differetial_on_measurement=False,

error_map=None,

):

self.Kp, self.Ki, self.Kd = Kp, Ki, Kd

self.setpoint = setpoint

self.sample_time = sample_time

self._min_output, self._max_output = None, None

self._auto_mode = auto_mode

self.proportional_on_measurement = proportional_on_measurement

self.differetial_on_measurement = differetial_on_measurement

self.error_map = error_map

self._proportional = 0

self._integral = 0

self._derivative = 0

self._last_time = None

self._last_output = None

self._last_error = None

self._last_input = None

self.dt_range = (0.01, 0.1)

try:

self.time_fn = time.monotonic

except AttributeError:

self.time_fn = ticks_seconds

self.output_limits = output_limits

self.reset()

def __call__(self, input_, dt=None):

"""

Update the PID controller.

Call the PID controller with *input_* and calculate and return a control output if

sample_time seconds has passed since the last update. If no new output is calculated,

return the previous output instead (or None if no value has been calculated yet).

:param dt: If set, uses this value for timestep instead of real time. This can be used in

simulations when simulation time is different from real time.

"""

ifnot self.auto_mode:

return self._last_output

now = self.time_fn()

if self._last_time is None:

dt = 0

elif dt is None:

dt = now - self._last_time

dt = _clamp(dt, self.dt_range)

elif dt <= 0:

raise ValueError('dt has negative value {}, must be positive'.format(dt))

if self.sample_time is not None and dt < self.sample_time and self._last_output is not None:

# Only update every sample_time seconds

return self._last_output

# Compute error terms

error = self.setpoint - input_

d_input = input_ - (self._last_input if (self._last_input is not None) else input_)

d_error = error - (self._last_error if (self._last_error is not None) else error)

# Check if must map the error

if self.error_map is not None:

error = self.error_map(error)

# Compute the proportional term

ifnot self.proportional_on_measurement:

# Regular proportional-on-error, simply set the proportional term

self._proportional = self.Kp * error

else:

# Add the proportional error on measurement to error_sum

self._proportional -= self.Kp * d_input

# Compute integral and derivative terms

self._integral += self.Ki * error * dt

self._integral = _clamp(self._integral, self.output_limits) # Avoid integral windup

if dt > 0:

if self.differetial_on_measurement:

self._derivative = -self.Kd * d_input / dt

else:

self._derivative = self.Kd * d_error / dt

else:

self._derivative = 0

# Compute final output

output = self._proportional + self._integral + self._derivative

output = _clamp(output, self.output_limits)

# Keep track of state

self._last_output = output

self._last_input = input_

self._last_error = error

self._last_time = now

return output

步骤4:初始化PID参数

根据手部追踪需求,设置X轴(水平)和Y轴(垂直)的PID参数:

printf("hello wo# 初始化X方向PID(目标:手掌中心对准屏幕中心)

g_pid = PID(

Kp=PID_KP,

Ki=PID_KI,

Kd=PID_KD,

setpoint=0, # PID目标值:屏幕中心X坐标

sample_time=0.02, # 采样时间20ms

output_limits=PID_OUT_RANGE_X # PID输出限制在舵机角度范围内

)

# 初始化Y方向PID(目标:手掌中心对准屏幕中心)

h_pid = PID(

Kp=PID_KP_Y,

Ki=PID_KI_Y,

Kd=PID_KD_Y,

setpoint=0, # PID目标值:屏幕中心Y坐标

sample_time=0.02, # 采样时间20ms

output_limits=PID_OUT_RANGE_Y # PID输出限制在舵机角度范围内

)rld!");

步骤5:通过手掌检测,获取手掌中心位置

根据手掌中心位置的X、Y坐标,送进PID计算偏移量,转换成舵机角度,并移动舵机

def adjust_servo_by_hand_x(hand_center_x):

global last_target_handle_x

#根据手掌中心X坐标,通过PID控制舵机角度

if hand_center_x is None:

return # 未检测到手

deviation = abs(hand_center_x - screen_center_x)

if deviation < 50:

return

# 调用PID计算目标角度(输入:当前手掌X坐标,输出:目标舵机角度)

hand_adjust_x = hand_center_x - screen_center_x

target_screen_position = g_pid(hand_adjust_x)

p, i, d = g_pid.components

if False:

print(f"p:{p}, i:{i}, d:{d}")

target_angle = pid_to_servo_x(-target_screen_position) #由于demo屏幕方向与坐标相反,需要对PID输出的值取反,根据实际情况调整

if False:

print(f"hand_center_x: {hand_center_x}, target_screen_position: {target_screen_position}, target_angle:{target_angle}")

last_target_handle_x = hand_center_x

# 移动舵机到目标角度

move_servo_x(target_angle)

步骤6:核心追踪循环

实时检测手部位置,通过PID计算调整舵机角度:

pri# 主循环

while True:

with ScopedTiming("总耗时", 1):

img = pl.get_frame() # 获取摄像头帧

dets = hand_det.run(img) # 手势检测推理

hand_center_x, hand_center_y = hand_det.draw_result(pl, dets) # 绘制结果并获取手掌中心

pl.show_image() # 显示图像

# 根据手掌位置控制舵机

adjust_servo_by_hand_x(hand_center_x)

adjust_servo_by_hand_y(hand_center_y)

gc.collect() # 垃圾回收ntf("hello world!");

调试技巧:让追踪更流畅

1.参数调整:如果追踪太迟钝,可增大P值;若震荡严重,可增大D值

2.死区设置:abs(deviation) < 20中的数值可根据实际情况调整,过滤微小抖动

3.角度限制:通过max(0, min(...))确保舵机不超出机械范围

4.帧率优化:定期调用gc.collect()进行垃圾回收,保持流畅运行

扩展玩法

更换模型:将手部检测替换为人脸、物体检测,实现更多追踪场景

多级调速:根据手部移动速度动态调整PID参数,实现"近慢远快"

联动应用:结合灯光、声音模块,打造互动感应装置

只需一套K230开发板,就能解锁无限创意!快来动手试试,让你的设备拥有"智慧之眼"吧~